Visit Wensui Group Manufacturer Online

2023-12-22 Page view:

Founded in 1990, Wensui Company initially operated on Guangzhou Avenue in the Haizhu District of Guangzhou City. Over time, the burgeoning business outgrew the original factory's capacity, prompting two expansions in 2000 and 2003. Consequently, Wensui relocated to its current production hub at No. 36 Dongxing Road, Chadong, Dalong Street, Panyu District, Guangzhou..

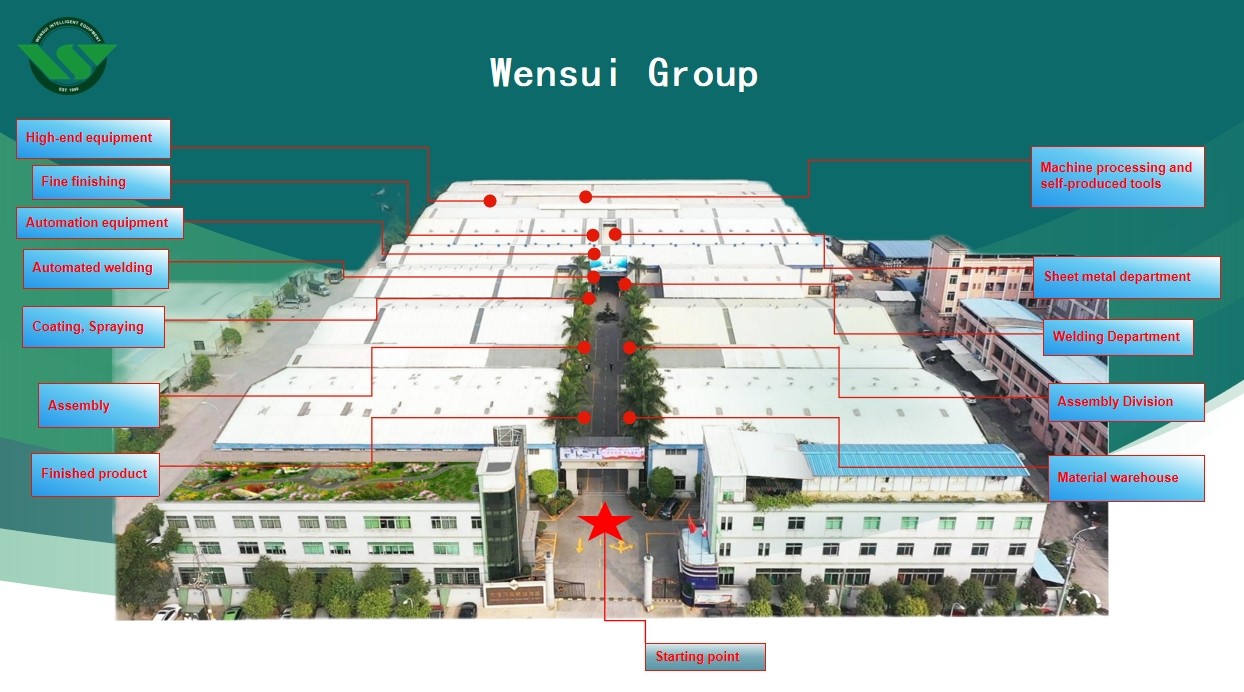

Spanning across over 50,000 square meters, the Wensui group production base distinguishes itself as one of the select few companies capable of comprehensive, end-to-end machinery and intelligent equipment manufacturing. This full-process production approach signifies a pinnacle of technical prowess and efficiency, enabling seamless progression from raw materials to intricate machining, assembly, and meticulous quality checks—a unique feat within the plastic auxiliary industry.

Wensui's identity bears the significance of both Chinese and Canadian flags. This symbolism underscores the company's commitment to advancing alongside the Party's vision, embodying loyalty to the nation and its people. Moreover, the fusion of the Wensui corporate flag with the Canadian flag signifies the integration of advanced technologies from both nations, leveraging the dual R&D engine advantages of Canada and China. This synergy empowers Wensui Group to drive innovation efficiently, propelling "Intelligent Manufacturing in China" onto the global stage.

Key Manufacturing Units at Wensui:

1. Incoming Material Warehouse: Supporting extensive material demands, this space facilitates the intricate processing of metals, wires, plastics, and other components essential to

Wens's product line.

2. Assembly Division: Responsible for integrating various parts into finished products, this department prioritizes optimized assembly processes, coordination among departments, and

equipment maintenance to enhance efficiency and quality.

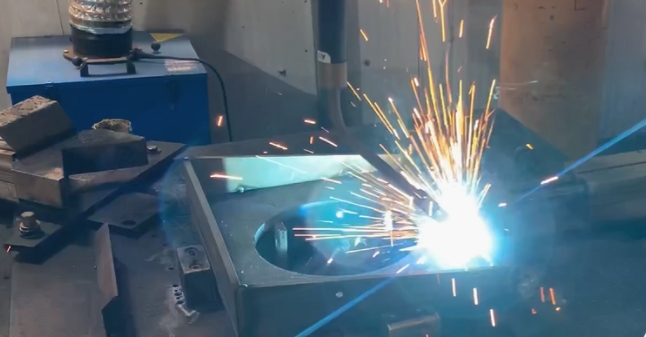

3. Welding Department: Critical for producing durable and reliable welded metal boxes, ensuring stability and resilience under demanding industrial conditions.

4.Sheet Metal Department: Utilizing stamping, punching, and bending processes to craft consistent, precisely shaped metal parts that cater to diverse product 4. Sheet Metal Department:

Utilizing stamping, punching, and bending processes to craft consistent, precisely shaped metal parts that cater to diverse product manufacturing needs.

5. Machining: Employing mechanical devices to alter workpieces' dimensions or properties, enhancing accuracy and consistency while minimizing human errors.

6. High-End Equipment: Wensui's investment in cutting-edge machinery, such as advanced CNC machine tools and laser cutting machines, significantly elevates product quality and

production efficiency.

7.Precision Manufacturing: Leveraging precision grinding and heat treatment processes to craft high-precision, durable knife sticks, ensuring superior quality and performance.

8. Fine Processing: This stage refines workpieces, minimizing errors and defects, thereby improving product accuracy, quality, and competitiveness.

9.Self-Made Devices: Wensui Group uniquely manages the entire production process, from raw materials to final output, of evaporators and condensers. This in-house approach ensures

steadfast quality and agility in responding to market fluctuations, setting Wensui Electronics at the forefront of the plastic auxiliary machinery sector.

10.Wensui's finished product warehouse: stringent quality control measures are upheld to ensure top-tier quality. Each product undergoes rigorous inspection, meeting and surpassing

standard requirements. With consistent and ample output, we reliably meet market demands, guaranteeing customers a steady and substantial supply.

By honing expertise, employing advanced technologies, and maintaining a full-process, self-made model, Wensui Group excels in both quality and innovation, positioning itself as a

frontrunner in the industry.

Thanks for visit Wensui group online !