How does Wensui Group write a green new answer sheet?

2023-09-22 Page view:

The 2023 government work report places green and low-carbon development in a more prominent position than ever before. The report proposes that this year we will promote the green transformation of development methods and promote energy conservation and carbon reduction in key areas. Guided by this goal, the burden on the industrial manufacturing sector seems to be heavier - according to data from the Ministry of Industry and Information Technology, energy consumption in the industrial sector accounts for about 65% of the overall national consumption. In addition, nearly 60% of the total amount of plastic waste recycling and reuse in China also comes directly or indirectly from industrial manufacturing. Green and low-carbon development in the field of industrial manufacturing is a key link in achieving carbon neutrality.

In 2023, the vision of green and low-carbon is shining into industrial manufacturing, and the pace of enterprise transformation and automation is constantly accelerating. For enterprises, green, energy-saving, and low-carbon are not only the scope of corporate social responsibility, but also a strategic imperative related to the survival of enterprises.

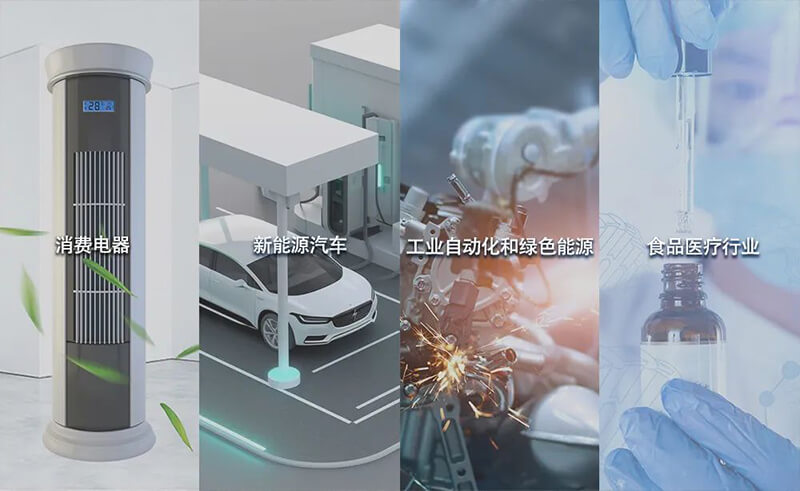

As one of the top ten plastic machine brands in China, Wensui Group has become a strong player in the industry after more than 30 years of deep cultivation. It shoulders the dual mission of being a practitioner and an empowerment on the green and low-carbon road. Its eight major product series are co builders of automation transformation and green sustainable development in the global pan industrial field. We provide partners with technologically advanced, reliable, and environmentally friendly plastic auxiliary products and water supply and supply solutions in fields such as consumer electronics, new energy vehicles, industrial automation and green energy, and the food and medical industry.

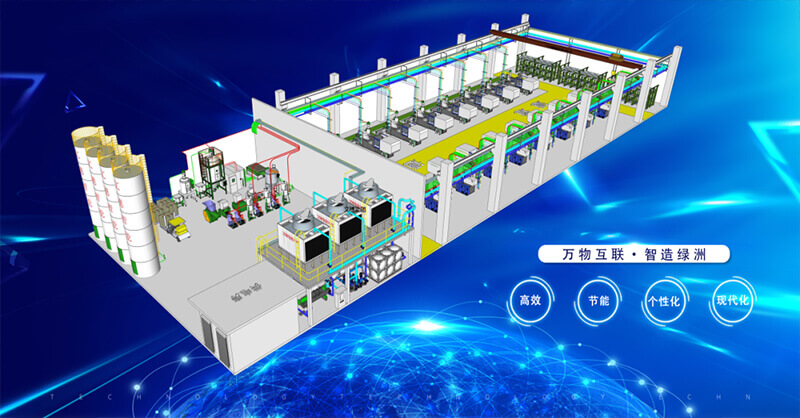

Internet of Things, Helping Enterprises Transform

Wensui Group's plastic auxiliary products cover sub fields such as household appliances, food and medical packaging, plastic industrial products, new energy vehicles, and are a system level solution supplier for plastic product production; Focusing on the energy-saving, low-carbon, and intelligent needs of enterprises for plastic product production, we plan, design, and construct the entire factory with water and electricity, supply, robotic arm automation, MES, AGV, etc. to help the global plastic industry achieve sustainable development and industrial upgrading.

What is a water supply system?

The central feeding system is designed for the production of plastic products in the molding workshop, achieving uninterrupted unmanned continuous molding operations. The combination of raw material varieties and multi-color materials can be changed according to needs, achieving full automation of material supply in the forming workshop and centralized raw material area, and achieving 24-hour continuous feeding operation for granular materials; By controlling the coloring process of each molding machine through multiple small microcomputers, the measurement accuracy, uniform mixing, and flexible color change are achieved, adapting to the requirements of multiple colors and varieties of products.

The central water supply system adopts a bi-directional and simultaneous design scheme for the entire injection molding workshop pipeline network. It adopts a highly automated program control system, including variable frequency control of water pumps, hierarchical control of water towers, and segmented control of screw chillers. Through system pressure and flow distribution, it achieves the lowest energy efficiency of the system, achieving consistent machine pressure, flow rate, and low return water pressure in the pipeline network, Thus achieving uninterrupted and continuous operation of water equipment with low energy consumption and high stability.

What are the advantages of water and material supply systems?

Efficient:

The central supply and water supply system can achieve centralized supply of cooling water and chilled water, as well as automatic supply of various raw materials. At the same time, it also takes into account the drying and color matching treatment of raw materials, as well as the proportional utilization of crushed and recycled materials, achieving highly automated control and monitoring in the injection molding workshop, and meeting the production needs of 24-hour non-stop.

Energy saving:

The central supply and water supply system is easy to operate, requiring only a few people to control the supply and water demand of the entire molding factory, thereby reducing a large amount of labor costs. Secondly, it reduces the placement and manipulation of auxiliary equipment next to the molding machine, and improves the utilization of space. In addition, due to the adoption of centralized control, a significant reduction in single machine equipment has been achieved, saving electricity and reducing maintenance costs.

Personalization:

The central supply and water supply system can design automation and intelligent solutions with high cost-effectiveness according to different users, process flow, workshop characteristics, and usage needs.

Image of modern chemical factory:

The central supply and water supply system will minimize the pollution caused by high temperature, noise, dust, sewage, and other factors to the molding production, thus maintaining a clean production workshop. The unique centralized dust recovery system makes cleaning more convenient and environmentally friendly, meeting the requirements of a 100000 level dust-free room and reducing noise. Ultimately, an unmanned automated production workshop can be achieved, establishing the image of modern chemical plant management, Truly achieve energy-saving and low-carbon.

The path of practice is never smooth. Wensui Group will also follow the vision of "Internet of Things, Manufacturing Oasis", with hard core technological strength and innovative spirit of exploration, continuously expand the radius of green and low-carbon development, and work together with partners to move towards a greener, more efficient, smarter, and better plastic industry.